How are we

enabling a more

sustainable

world?

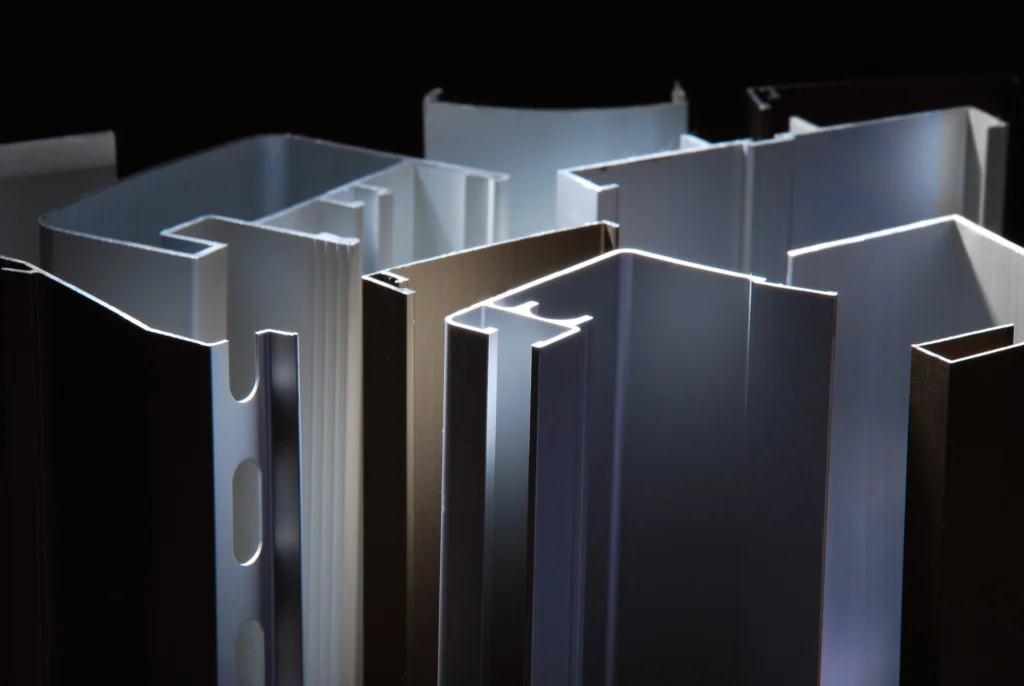

GREEN MANUFACTURING

All GWS manufacturing and processing plants use clean energy. With a vision of being Carbon Neutral in Scope 2 emissions by 2027, all GWS’s manufacturing facilities are equipped with rooftop solar panels.

Co2 Reduction in kgs

5,44,199

Usage Covered by Solar

100%

Equivalent Trees Planted

8,998

Co2 Reduction in kgs

1,22,142

Usage Covered by Solar

40%

Equivalent Trees Planted

2,020

Co2 Reduction in kgs

5,05,500

Usage Covered by Solar

51%

Equivalent Trees Planted

8,358

Co2 Reduction in kgs

5,44,199

Usage Covered by Solar

100%

Equivalent Trees Planted

8,998

Co2 Reduction in kgs

1,22,142

Usage Covered by Solar

40%

Equivalent Trees Planted

2,020

Co2 Reduction in kgs

5,05,500

Usage Covered by Solar

51%

Equivalent Trees Planted

8,358

Low Embodied Carbon Products Collaborations

- With potential savings of 60% plus on Scope 3 emissions as against the world average, GWS has one of the lowest embodied façade product offering (EPD on request).

GWS Low Carbon Aluminium Offering

- World Average: 20 KgCO2/Kg.

- GWS Offering 2.00-2.50 KgCO2/Kg.

- 90% below Global Average -EPD Available.

GWS CARBON NEUTRAL

SILICON OFFERING

- Savings of approximately 7kgs CO2 eq/ 1 kg of SI.

- 100% below Global Average -EPD Available.

GWS LOW CARBON

GLASS OFFERING

- Savings of around 30% to 40% for insulated glass as compared to world average.

- EPD Available.

GWS LOW CARBON

GLASS OFFERING

- Savings of around 30% to 40% for insulated glass as compared to world average.

- EPD Available.

Zero Waste Program

GWS follows a well defined waste recycling program, ensuring 100 % recycling and zero landfill/other waste.

Aluminium Waste

All scrap goes for recycling

to GWS’s defined

partners.

Silicone Waste

It is disposed-off through GWS’s recycling program with DOW.

Glass Waste

All scarp goes for recycling to GWS’s defined processing partners.

Coating

All plants are equipped with Effluent Treatment Plant (ETP) plants to treat/recycle pre-treatment waste.

Electronic Waste

It is disposed off as per the Government of India E-Waste rules, with a Zero Emission policy.

Ancillary Waste

GWS has tied-up with existing industrial areas for proper disposal through available programs.

Aluminium Waste

All aluminium scrap goes for

recycling to our defined

partners.

Silicone Waste

It is disposed off through our recycling program with DOW An other g for recycling processin

Glass Waste

Any broken glass pieces or other glass wastage goes for recycling to our defined processing partners.

Coating

All plants are equipped with Effluent Treatment Plant (ETP) plants to treat/recycle pre-treatment waste.

Electronic Waste

It is disposed off as per the Government of India E-Waste rules, with a Zero Emission policy.

Ancillary Waste

GWS has tied-up with existing industrial areas for proper disposal through available programs.